Multi Point Optical Monitor

Optical monitoring in large area deposition systems requires a new innovative method to reduce cost and yet increase measurement performance.

The Telemark Optical Monitor represents that breakthrough in distributed monitoring techniques that both reduces cost and improves performance. This instrument is built upon an open SQL data base containing all the run and setup data allowing the user to easily configure the system, run it and access the run data either from the operating computer or from any computer on the network in real time. The system is application driven with an easy setup tool for configuration of each spectrometer in the system.

Large systems take advantage of the distributed nature of the monitor, placing optical modules at various locations on the coating system up to 300 meters from the control computer thereby reducing the cost of fiber optic cables.

- Multiple Wavelength Analysis

- Up to 32 measurement points

- Transmission and Reflection

- Trending of color and wavelength data

- Complete Fixturing Process Support

Broadband spectrographic measurement allows the system to display wavelength versus transmission or reflection through the entire visible spectrum many times a second. Trending of calculated color and specific wavelengths allow the operator to control his process with ease. Set points can be configured to notify the operator when the controlled process is moving out of control so corrections can be made prior to loss of product. These same spectrographic measurements reduce the setup time of complex coatings by allowing laboratory quality measurements to be made in the coater during the setup process.

Dual and single beam modes are available for long production runs of many hours.

Automatic calibration and background functions are available for use between measurements of product.

Large easy to view displays provide at a glance understanding of where your process is going. Displays as large as 48” LCD’s are available.

Full integration to your coating system is provided with all necessary hardware, fixtures and digital interfaces. Process support is available from our experienced engineers and scientists to ensure maximum system effectiveness.

| UV/Vis HR-200 - 850 | UV/Vis HR-200 -1100 | UV/Vis LR-350 -800 | NIR LR-900-2200 | |

|---|---|---|---|---|

| Spectrometer Type | Asymmetrical crossed Czerny-Turner | Asymmetrical crossed Czerny-Turner | Asymmetrical crossed Czerny-Turner | Asymmetrical crossed Czerny-Turner |

| Focal Length | 42 mm input; 68 mm output | 42 mm input; 68 mm output | ||

| Entrance Aperture | 25 µm wide slit | 25 µm wide slit | 25 µm wide slit | 25 µm wide slit |

| Grating | 600 L / mm, Blazed at 300 nm | 600 L / mm, Blazed at 300 nm | 100 L / mm | |

| Wavelength Range | 200-850 nm | 200-1100 nm | 400-800 nm | 900-2200 nm |

| Pixel Resolution | 0.164 nm / pixel | 0.246 nm / pixel | 0.439 nm / pixel | 2.54 nm / pixel |

| Optical Resolution | <1.5 nm FWHM | <1.5 nm FWHM | <1.5 nm FWHM | <4.6 nm FWHM |

| Stray Light | <0.05% at 600 nm; 0.10% at 435 nm | <0.05% at 600 nm; 0.10% at 435 nm | n/a | n/a |

| Signal to Noise ratio | 300:1 (at full signal) | 300:1 (at full signal) | 1500:1 (at full signal) | >10,000:1 @ 100 ms integration |

| Integration Time | 3 ms - 10 seconds | 3 ms - 10 seconds | 10µs - 10 seconds | 1 ms -2 seconds |

| A/D Resolution | 16 bit | 16 bit | 14 bit | 16 bit |

| Dynamic Range | 1300:1 for a single acquisition | 1300:1 for a single acquisition | 4600:1 for a single acquisition | 1000:1 for a single acquisition |

| Detector | 3648 element CCD array | 3648 element CCD array | 1024 pixel linear CMOS | 512 pixel InGaAs linear array |

| Pixel Size | 8 μm x 200 μm | 8 μm x 200 μm | 7.8 x 125 µm | 25 µm x 250 µm |

| Typical Stability | < .1% F.S. / Hour Single Beam | < .1% F.S. / Hour Single Beam | < .1% F.S. / Hour Single Beam | |

| Computer to OM | 100 meters per leg | 100 meters per leg | 100 meters per leg | 10 meters per leg |

| Power Requirements | 100 – 240 VAC, 50-60 Hz | 100 – 240 VAC, 50-60 Hz | 100 – 240 VAC, 50-60 Hz | 100 – 240 VAC, 50-60 Hz |

| Light Source | Thermally stabilized low voltage QH lamp | Thermally stabilized low voltage QH lamp | Thermally stabilized low voltage QH lamp | Thermally stabilized low voltage QH lamp |

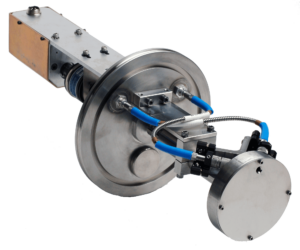

For in-situ optical monitoring it is often desirable to monitor coatings via. a witness chip assembly. The Telemark witness chip changer offers users reflection or transmission measurements. The witness chip magazine manages 50 optical monitoring positions.