Quartz Crystal Deposition Controllers

Model 861 Deposition Controller

The Telemark 861 electron beam source quartz crystal (QCM) deposition controller is a drop-in replacement for the Maxtek 360 and Telemark 860 units. This controller provides pin for pin replacement for old Maxtek and Telemark units. Users can transfer existing processes and setup configurations from old units directly to the 861. The 861 is also an excellent replacement for the IC6, IC5, XTC3, XTC2, SQC-310 and IC6000.

Modern color LCD touch screen interface and capability for I/O upgrades and additional sensor heads makes this tool excellent for system upgrades and OEM users alike.

The unit contains an extensive material library and user definable materials. Storage capability of 99 processes of up to 999 layers each.

Proprietary oscillator for 5MHZ or 6MHz operation and high resolution of < 0.01A

Units come standard with 2 sensor inputs (upgradable to 4 sensors) and and 8 I/O channels (upgradable to 32 I/O channels) which can be used for ancillary system operations such as pocket indexing, shutter activation, and sweep selection.

Model 862 Deposition Controller

Same features as the 861 but in a chassis with 7-inch touchscreen and capabilities to control co-deposition, average up to 4 sensors simultaneously

-

- High frequency internal reference oscillator provides <0.01A resolution for aluminum

- Operates with 5 MHz or 6 MHz crystals

- All new innovative crystal oscillator design for outstanding stability and noise immunity

- Extensive materials library, also allowing for user definable materials

- Color LCD touch screen for graphical and numerical display of primary real-time process data, providing an intuitive and user friendly operator interface

- Touch screen capabilities: In-process parameter modification, Process and Layer editor, I/O status and control

- Real time graphical display of: Power v/s time, Rate v/s time, Thickness v/s time, Rate deviation v/s time

- All system, film and setup files may be saved via a front panel USB port, as well as uploaded to instrument

- Can accommodate up to 99 processes of 999 layers each

- Standard unit has 2 crystal sensor inputs and 2 isolated rate control analog output drivers, expandable to 4 each.

- 8 relay isolated outputs and 8 optically isolated inputs (active or passive mode), with the option to upgrade to 32 ea., for ancillary operations such as pocket indexing, sweep selection and sensor selection.

| Model 861 | Model 862 | |

|---|---|---|

| Co-Deposition | ||

| Crystal Averaging | ||

| Oscillator Included | ||

| Hand-Held Remote Included | ||

| Display | 5-inch Color LCD Touchscreen | 7-inch Color LCD Touchscreen |

| Sensor Crystal Frequency | 5 or 6 MHz | 5 or 6 MHz |

| Resolution | <0.02Hz (<0.01A for Al @ 6MHz) | <0.02Hz (<0.01A for Al @ 6MHz) |

| Accuracy | +/- 0.5% thickness | +/- 0.5% thickness |

| Thickness Display | 0.000 - 999.9 kÅ | 0.000 - 999.9 kÅ |

| Power Display | 0.0 - 99.9 % | 0.0 - 99.9 % |

| Rate Display | 0.0 - 999 Å/s | 0.0 - 999 Å/s or 0.00 - 999 Å/s |

| Measurement Update | 10 per second | 10 per second |

| Control signal Update | 10 per second | 10 per second |

| Inputs | 8 standard (32 max.) optically isolated, active (12 to 24V DC), or passive (contact closure) | 8 standard (32 max.) optically isolated, active (12 to 24V DC), or passive (contact closure) |

| Outputs | 8 standard (32 max.) relay contacts, max 2A, 50 DC | 8 standard (32 max.) relay contacts, max 2A, 50 DC |

| Analog Outputs | 2.5, 5 or 10 volts @ 20 ma. 0.002% resolution | 2.5, 5 or 10 volts @ 20 ma. 0.002% resolution |

| Power Input | 90-264 VAC, 47-63 Hz | 90-264 VAC, 47-63 Hz |

| Rack Height | 2U (3.5 inches, 88mm) | 3U (5.25 inches, 133mm) |

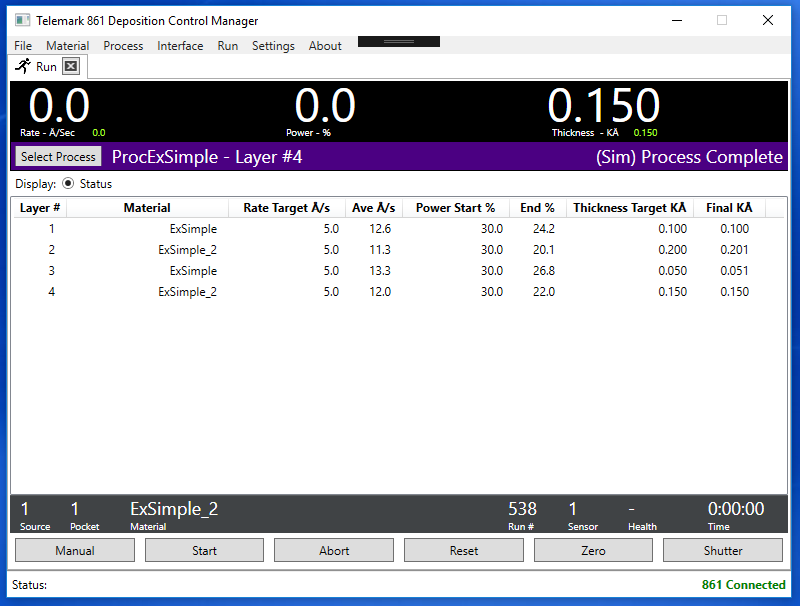

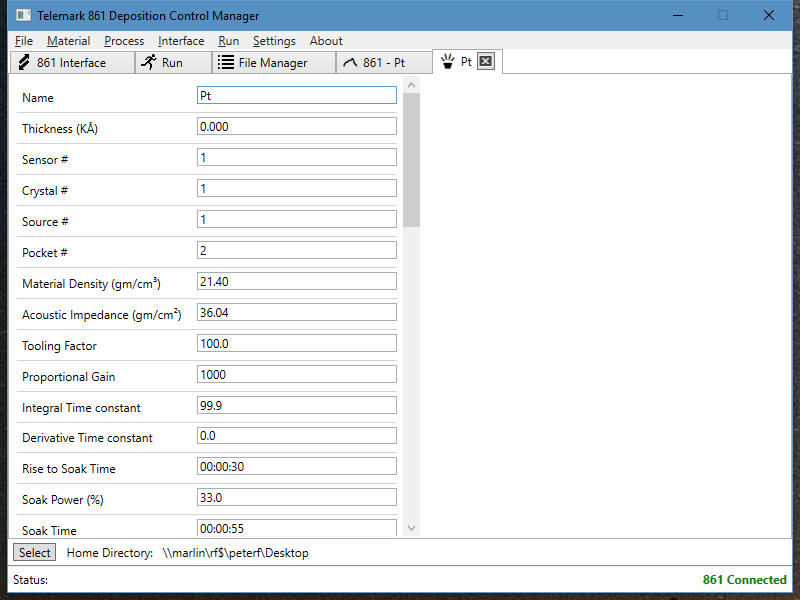

Windows DCM Software

The DCM software can create and edit Processes and Materials on a Windows computer that can be transfer via USB to the 861 or 862. When connected via RS-232 or Ethernet can edit processes and materials directly on the 861 or 862 and it can remotely operate the 861 or 862.

When the DCM software is connected it automatically makes two files in the working directory for each process run, a summery file that includes averages and a file with the stream of data of Rate, Rate Deviation, Power, and Thickness.