product breakdown

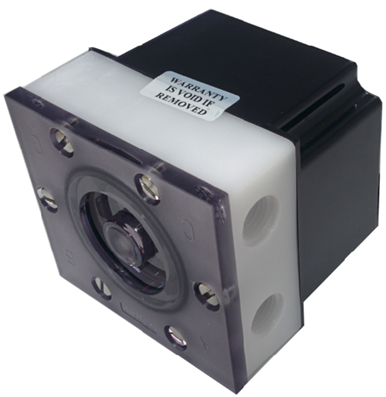

Single Pocket Sources

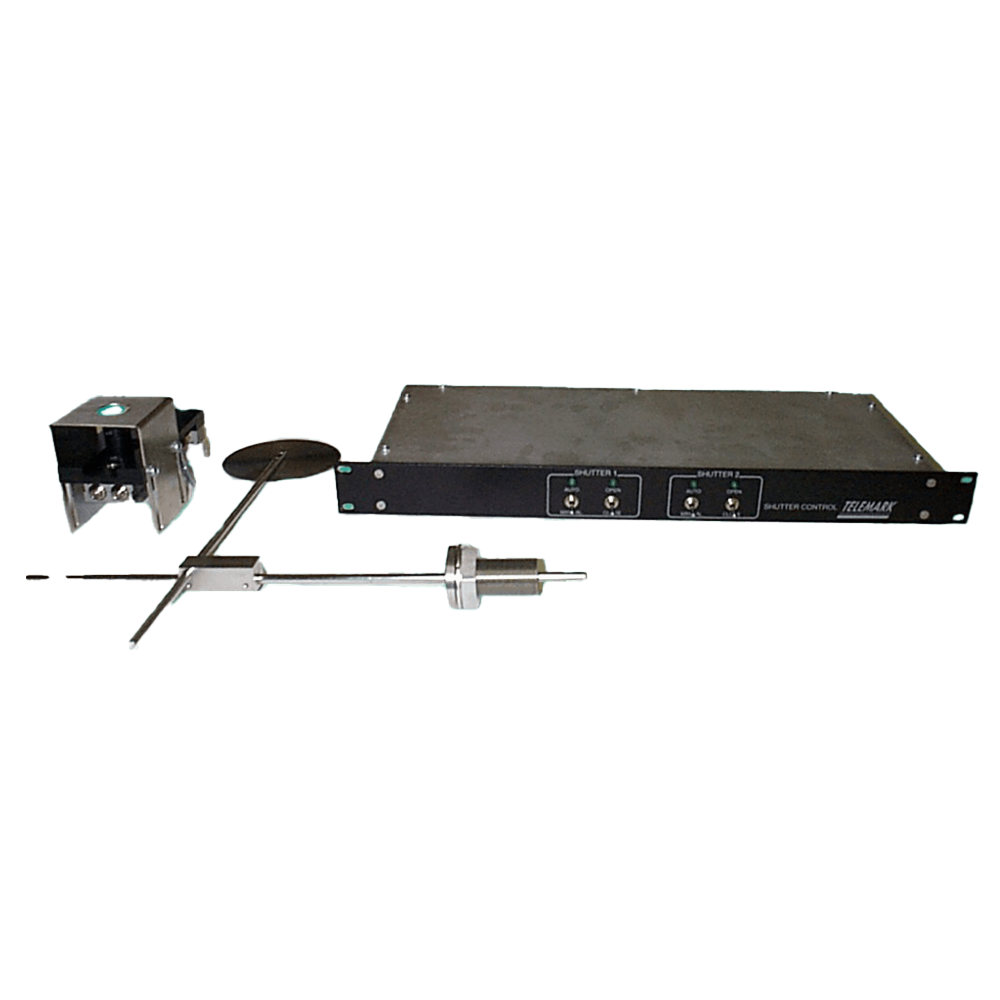

Telemark offers single pocket e-beam sources from 1.5cc to 160cc. Telemark single pocket source offerings include High Vacuum (10-7 torr) and Ultra High Vacuum (10-11 torr) models. Installation kits and source shutters can be supplied. Please contact Telemark for your ebeam source requirements for model and configuration assistance.

detailed information

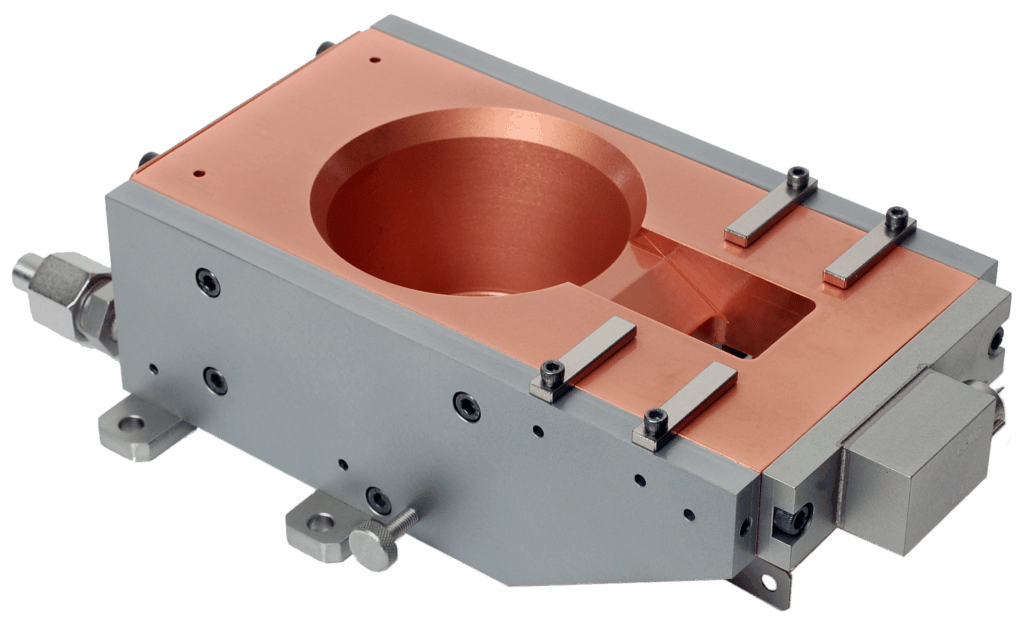

Model 211

High Performance in a Small Package with Crucible Volumes to 15cc.- Rated at 6kW* of power when operated at voltages from -6 to -10kV.

- Compact design for use in small research and development systems or wherever space is an important consideration.

- Coils sealed in stainless steel cans are standard

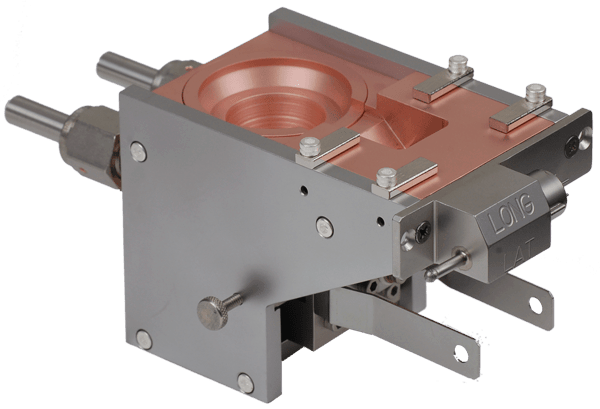

Model 272 and Model 259HV

Performance Proven in High-Power Production Applications- Available in crucible volumes up to 100cc for long, uninterrupted evaporation.

- Rated at 14kW* when operated at -10kV.

- Capable of evaporating high rates of material such as aluminum. This makes the model 272 ideal for processes that require a coating layer of one micron or more.

- The 272 is also well suited for operation at lower power levels where a large capacity for subliming materials might be required

| Model 211 | Model 259HV/272 | |

|---|---|---|

| 1.5cc | 211-05 | |

| 4cc | 211-04 | |

| 7cc | 211-07 | 272-01 |

| 15cc | 211-15 | 272-02 |

| 25cc | 272-03 | |

| 30cc | 272-30 | |

| 40cc | 272-04 | |

| 100cc | 272-05 | |

| 160cc | 259-50 |

| Model 211 | Model 259HV/272 | |

|---|---|---|

| E-Beam Deflection | 270° | 270° |

| Power Rating | 6 kW* | 14 kW* |

| High Voltage Range | -6 kV to -10 kV | -6 kV to -10 kV |

| Lateral Coil Resistance | 7.5 ohms | 3.0 ohms |

| Long. Coil Resistance | 9.5 ohms | 9.6 ohms |

| Water Requirements | 2 gpm(min.)@ 60-70°F (15-21°C) | 3 gpm(min.)@ 60-70°F (15-21°C) |

contact the Telemark sales team

Telemark's sales team will answer your questions—

Upon completing the form, a member of our team will reach out via email to answer your questions about our products.