product breakdown

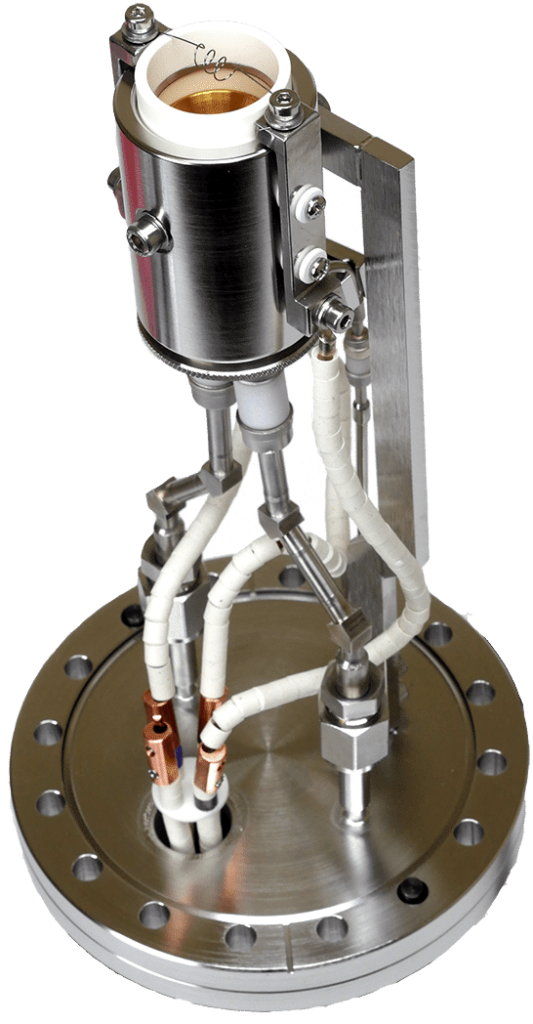

UHV Ion Source

The Mini is a constant DC filtered Source, which can be pumped into the10^-10 Torr vacuum range, capable of energies up to 225eV, with beam current of up to 1.5 amps in oxygen, nitrogen or argon (500W maximum). The ion source head, with feedthroughs and electrical connections, is installed on a single 6” CF Flange (or 4 ½” CF, if a separate 2 ¾” CF port is available for the electrical connector), and is bakeable to 250°C, without cooling water.

Price includes source with single filament, feedthroughs, and one mass flow controller, all mounted on 6” CF, with power supply and cables for installation. Bakeable mass flow controller upgrade available at additional cost.

detailed information

- Available on CF flange

- Power supply now comes with touch screen interface.

- Touch Screen for allow ease of use.

- Multi-Mode system operation – Continuous, Pulse, Gas Purge, Substrate Pre-clean all at the touch of the screen.

- Save regularly used deposition procedures to file. Save up to 15 separate files with all operational parameters.

- Ion beam energies up to 225eV.

- Ion Beam power to 500 watts.

- Anode currents to 5 amps.

- Full-time use of high purity oxygen.

- Highly efficient patented gas injection design greatly reduces gas load.

- Direct water-cooling to reduce maintenance, radiation load and venting delays.

- Extremely low maintenance. The patented design utilizes a specially coated anode, that resists build-up of electrically insulating oxide coatings. No need to change anodes for different gases.

- Extremely stable operation in IAD processes due to patented electrode design.

- Broad – beam divergence for large area coverage with a uniform ion flux.

- Rapid start-up – Only 3 seconds to stable operation from Start.

- Special Coiled Filaments provide >12 hours in pure oxygen per filament.

- Pulse-mode Operation for ion-assistance of radiation-sensitive film materials such as many commonly used infrared and UV thin film materials eg MgF2 & LaF2. For further information please refer to separate information sheets.

- Gas Purge Mode provided to allow routine purging of gas lines. Automatically switches off at pre-set timeout or when gas flow reaches < 1% of flow range.

- Pre-deposition Clean Mode provided to easily pre-clean the substrates immediately prior to deposition.

- Remote Control & Monitoring of process parameters. Remote control through RS232 protocol.

| Mini UHV | |

|---|---|

| Source Diameter | 47mm diameter by 70mm long (1.86” x 2.74”) |

| Source Weight | 1.4 kgs (approx. 3 lbs) |

| Beam Power | Anode volts selectable to 225 volts; anode power 500 W |

| Anode Current | Maximum 5 amps under manual or automatic beam control |

| Beam Divergence | Wide beam divergence in excess of 80 degrees |

| Gas Flow | Approximately 7sccm argon required to produce 2 amps (typical) |

| Cooling Water | Minimum 2.3 liters/minute. Water flow is constantly monitored |

| Power Unit Dimensions | 135mm x 480mm x 406mm |

| Power Unit Weight | 28 kgs (60lbs) |

- Dual Gas DG. Option provides facility to deliver either of two installed gases in either pure gas or specified gas mix ratio. Gas mixture is set from the touch screen.

- Mounting Hardware MH. Several options are available. The mounting brackets are clamped to a special gas feedthrough

contact the Telemark sales team

Telemark's sales team will answer your questions—

Upon completing the form, a member of our team will reach out via email to answer your questions about our products.