product breakdown

Ion Sources

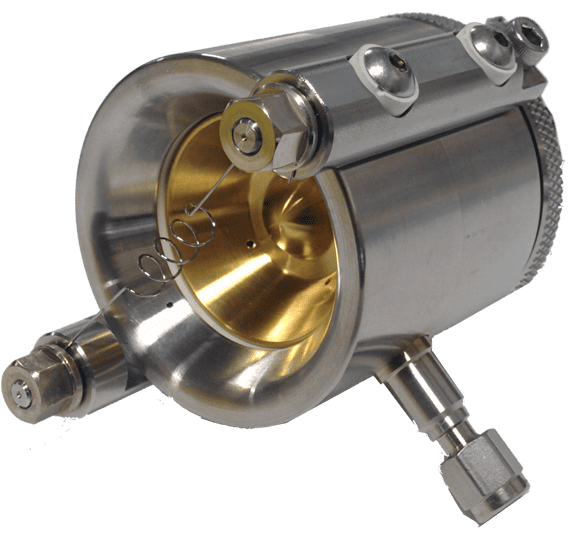

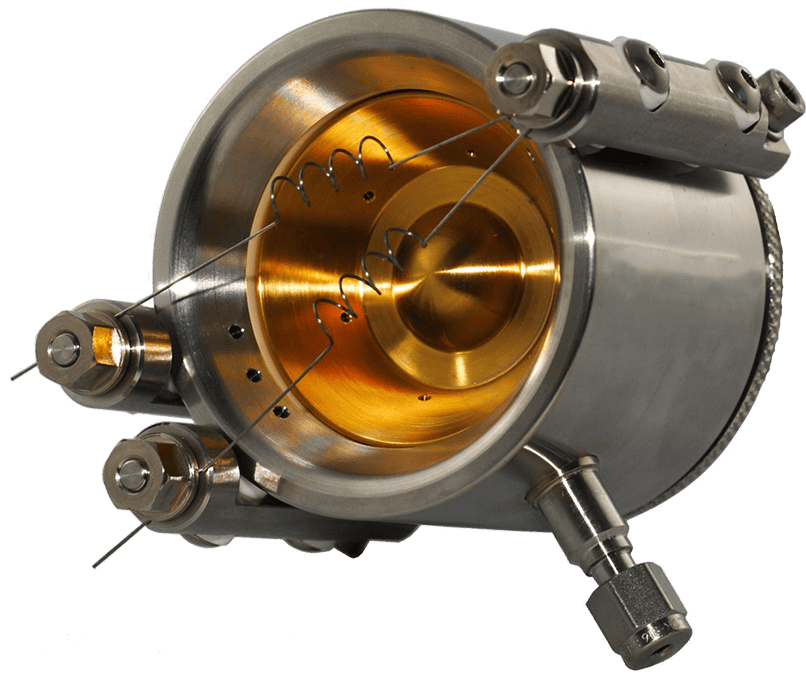

The Gridless End-Hall Ion Sources have been specially developed to provide a cost effective solution for ion assisted vacuum processes from small to large sized deposition systems. The sources provide an extremely reliable and maintenance-free up to 3kW source for many applications in PVD processes.

The compact design and rugged construction allows easy installation to both new and existing vacuum deposition systems.

detailed information

- Ion beam energies up to 300eV

- Ion beam currents to 15 amps

- Full-time use of high purity oxygen, argon or nitrogen.

- Highly efficient design greatly reduces gas load

- Water-cooled to reduce maintenance and radiation load

- Extremely low maintenance. The patented design utilizes a specially coated anode, which resists build-up of electrically insulating oxide coatings. No routinely replacement parts.

- Extremely stable operation in IAD processes

- Broad – beam divergence for large area coverage with uniform ion flux.

- Pulse-mode operation for ion-assistance of radiation-sensitive film materials such as many commonly used infrared and UV thin film materials eg MgF2 & LaF2. For further information please refer to separate information sheets.

- Remote Control and Monitoring – all control through an RS232 interface

| Model 750 | Model 1250 | Model 2000 | Model 3000 | |

|---|---|---|---|---|

| Source Diameter | 63mm diameter by 64mm long (2.48” x 2.53”) | 74mm diameter by 61mm long (2.91” x 2.4”) | 114mm diameter by 93mm long (4.49” x 3.66”) | 114mm diameter by 93mm long (4.49” x 3.66”) |

| Source Weight | 1.4 kgs (approx. 3 lbs) | 1.4 kgs (approx. 3 lbs) | 4 kg (approx. 8.5 lbs) | 4 kg (approx. 8.5 lbs) |

| Beam Power | Anode volts selectable to 225 volts; anode power 750W | Anode volts selectable to 225 volts; anode power 1250W | Anode volts selectable to 300 volts; anode power 2000W | Anode volts selectable to 300 volts; anode power 3000W |

| Anode Current | Maximum 5 amps under manual or automatic beam control | Maximum 5 amps under manual or automatic beam control | Maximum 7 amps under manual or automatic beam control | Maximum 10 amps under manual or automatic beam control |

| Beam Divergence | Wide beam divergence in excess of 80 degrees | Wide beam divergence in excess of 80 degrees | Wide beam divergence in excess of 80 degrees | Wide beam divergence in excess of 80 degrees |

| Gas Flow | Approximately 7sccm argon required to produce 2 amps (typical) | Approximately 7sccm argon required to produce 2 amps (typical) | Approximately 8sccm argon required to produce 2 amps (typical) | Approximately 8sccm argon required to produce 2 amps (typical) |

| Cooling Water | Minimum 2.3 liters/minute. Water flow is constantly monitored | Minimum 2.3 liters/minute. Water flow is constantly monitored | Minimum 2.5 liters/minute. Water flow is constantly monitored | Minimum 4.5 liters/minute. Water flow is constantly monitored |

| Power Unit Dimensions | 135mm x 480mm x 406mm | 135mm x 480mm x 406mm | 135mm x 480mm x 406mm | 180mm x 525mm x 435mm |

| Power Unit Weight | 28 kgs (60lbs) | 28 kgs (60lbs) | 30 kgs (66lbs) | 30 kgs (66lbs) |

Optional Features Available –

- Dual Filament. Electronic system detects filament failure and auto switches to second filament.

- Dual Gas This feature provides use of either pure gas delivery or a mixture of two gases in any ratio.

contact the Telemark sales team

Telemark's sales team will answer your questions—

Upon completing the form, a member of our team will reach out via email to answer your questions about our products.