New 274-0150-1 E-Beam Source Emitter

Telemark announces a new 270-degree electron beam source emitter with improved Arc Resistance. The new design incorporates improved insulator shielding to resist arcing, allowing for

Telemark announces a new 270-degree electron beam source emitter with improved Arc Resistance. The new design incorporates improved insulator shielding to resist arcing, allowing for

At the 2018 MRS Fall Meeting, Joshua Gurian of Telemark is presenting a talk titled “Improved TCO Process Stability Using In Situ 4-Point Probe Sheet

Hope to see you at the 2018 MRS Fall Meeting & Exhibit, November 27-29 booth 1125 Hynes Convention Center, Boston, Massachusetts

Dear Friends and Colleagues, The Telemark organization has been severely shocked by the sudden passing of Jim Colbridge, our Sales Manager. He was a good

You can now shop at telemark.com/shop for Spare Parts E-Beam Source Crucible Liners E-Beam Source Spare Parts and Crucibles E-Beam Source Feedthroughs Ion Source Filaments

Telemark announces the new Loyalty Rewards program. Customers who purchase all the quartz crystals and consumable E-beam parts they require from Telemark are eligible for

Great to see everyone who stopped by our booth at SVC TechCon 2018 in Orlando. See you next year in Long Beach California.

Once again, Telemark is showing its incredible depth in physical vapor deposition technology innovation by capturing an ever increasing market share in the QCM market.

Telemark Low Pressure Ion Sources consistently produce the highest index TiO2 films at ambient temperatures Telemark research lab continues to test materials using the Telemark

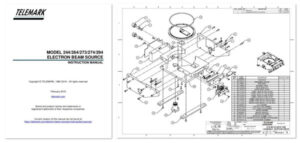

Telemark announces that in addition to product brochures we now have product manuals and drawings PDFs available on our website. Drawing PDFs have dimension drawings

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |